Question: Can a Grundfos CRE-DP be mounted inline off the floor?

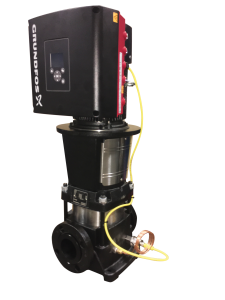

Answer: Yes it can. There are two ways to install it off the floor. The first is to fabricate a stand just like pictured here.

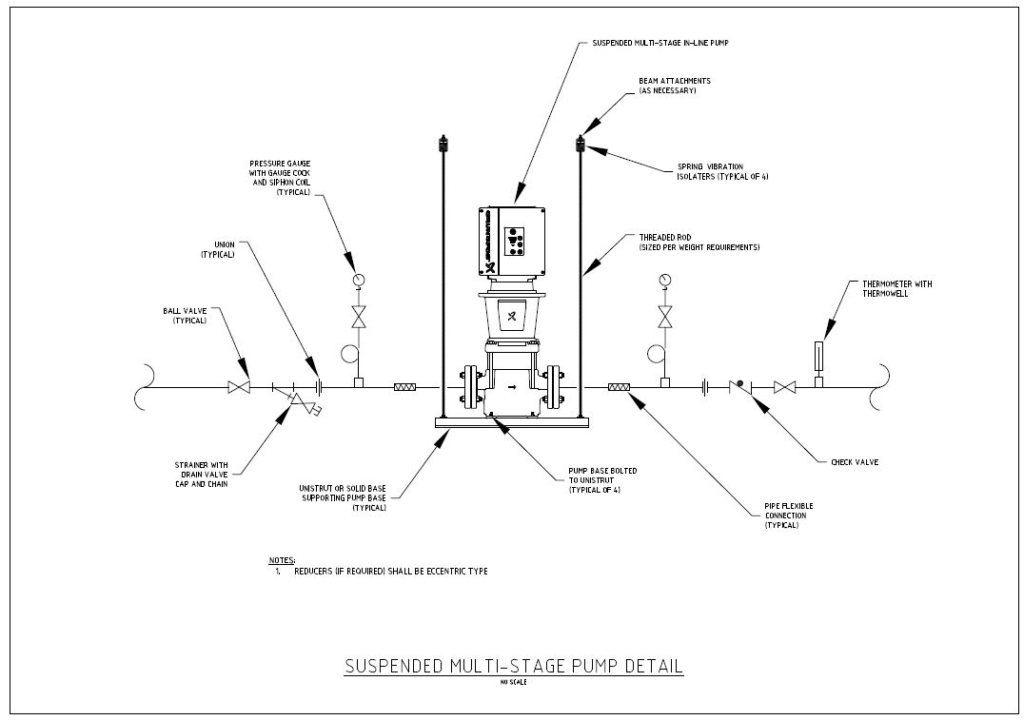

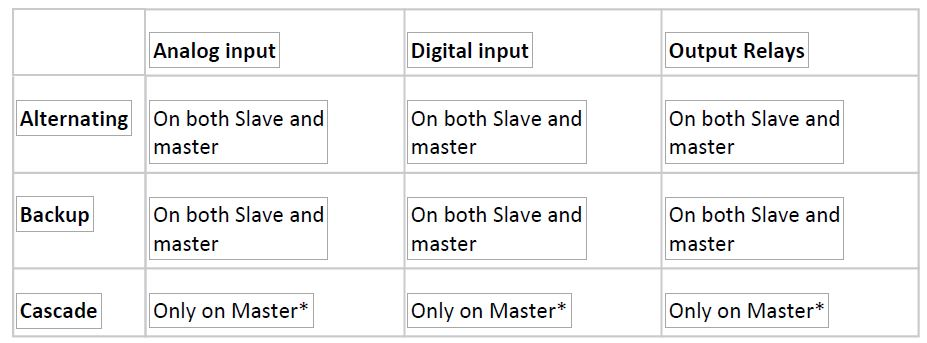

The second option is to suspend it per the factory supplied drawing shown below.

The CR series vertical multi-stage pump is a home run with specifying engineers due to using only 1/5 the space of a comparable base mounted pump. It also includes the VFD, DP sensors and integrated logic controls.

For the installing mechanical contractors, they save cost by no longer having to add suction diffusers, pouring housekeeping pads or hiring subcontractors to install external VFDs.

For additional information, contact your local Grundfos wholesaler.

Question: What is the replacement type of grease for CRE motors?

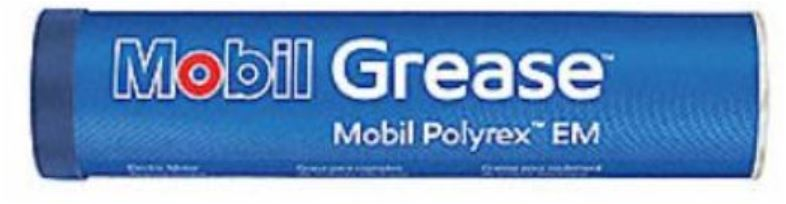

Answer: The Grundfos MLE motors (up to 5HP) use Lithium based electric motor bearing grease, which is not compatible with polyurea based electric motor greases that are standard in other manufacturer’s motors.

Grundfos uses Mobile Unirex N3 at the MLE factory. This information is printed on a tag on the motor housing. A lithium-based grease compatible with this must be used. The Grundfos order info for the Lithium-based grease Cartridge is P/N. 91079414 and is also available through Grainger. The MLE motors are in the CR, CRE, VLSE and VLSE E-Solutions series (up to 15HP).

For the Baldor motors used on models 15HP and larger, Darmex RPL-707 high temperature grease is recommended as listed in the Grundfos installation and operations manual.

Installers Tip – When commissioning, bring a label maker and leave the re-order numbers for this and the replacement seal cartridge kit labeled on the pump. It’s good professional courtesy for the building owner’s staff for future concerns.

Another useful tip is to use the grease reminder message that automatically shows up on the pump head screen and have the controls contractor add it as a data point to the BMS. It takes the all the guess-work out from when to service them every time.

This subject often gets glossed over but if not paid attention to will cause expensive damage your investment in the pumps.

The factory recommended preventative maintenance is every six months for extreme use, once a year for severe use and every three years for standard use applications. Grundfos E-Solutions MLE models 10 HP and under are permanently sealed with no lubrication required.

For additional information, refer to the installation and operations manual that is supplied with the pump.

Question: Does Grundfos offer condensate package system that you could provide information about?

Answer: Grundfos does not currently offer a condensate pump package in their line. However, Webb Pump, a division of the F W Webb Company partners with Grundfos using the CR series in their custom Pure Pro branded condensate packages.

The proprietary PurePro Stainless Steel Condensate Return System from F.W. Webb is built around the Grundfos immersion-style, vertical multi-stage pump. It is offered in simplex and duplex models, in three standard stainless-steel receiver sizes: 25-gallon, 50-gallon and 100-gallon. The standard duplex model comes complete with a mechanical duplexing level switch and an integral, pre-wired control panel with circuit protection and motor starters.

Options for these systems include sight glasses, temperature gauges, temperature transmitters, as well as stainless steel pump discharge heads. Systems can even be built as vacuum-systems. Keep in mind that the maximum temperature cannot go higher than 180 degrees due to maintaining the NPSH required.

Question: What’s the difference between a Grundfos CR and a CRE-DP?

Answer: The CR is the standard Grundfos multi-stage pump that has been used for years for industrial process and boiler feeds. It is known as a bullet proof pump and a better choice over a base mounted design for higher head applications.

The CRE-DP is the same multi-stage pump but it his configured for HVAC applications. The “E” in the CRE-DP stands for “electronic drive” so it has a integrated VFD. The “DP” refers to the built in Differential Pressure sensors. By having these components along with the most important part, Grundfos self- optimization logic this series is the most energy efficient, reliable and lowest maintenance cost of any pumps in the industry.

For specifiers designing a new building, it is the preferred pump over base mounted models due to taking up about 1/5th the floor space, no longer required is the concrete housekeeping pad, elimination of expense of suction diffusers and a longer life cycle.

For additional information, go to https://grundfos.com.us or contact your local supplier.

Question: Does the Grundfos Go App that we have for our Magnas work on the CRE-DP series? Currently we can change the setpoint but cannot see any additional setting or status information on the pump head. Would like to see more information.

Answer: Yes, the Grundfos Go works on ALL commercial E-Solutions pumps that have MLE motors and drives such as the Magna1, Magna3, TPE3, CRE, CRE-DP, CMBE, HYDRO MPCE series.

From the menu, you can change changes in the setpoint, control mode and a many other options.

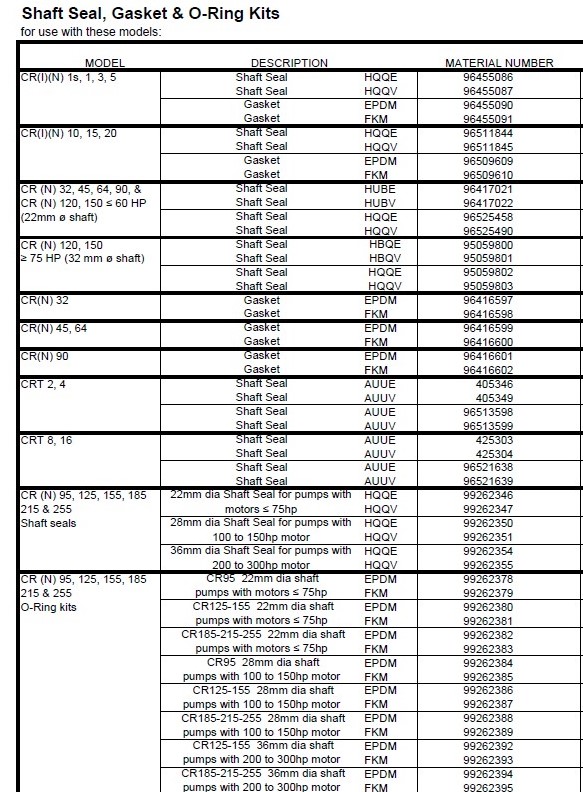

Question: I received a replacement stack kit but the gasket and O-ring were not included. What is the part number for a CRE 45-1?

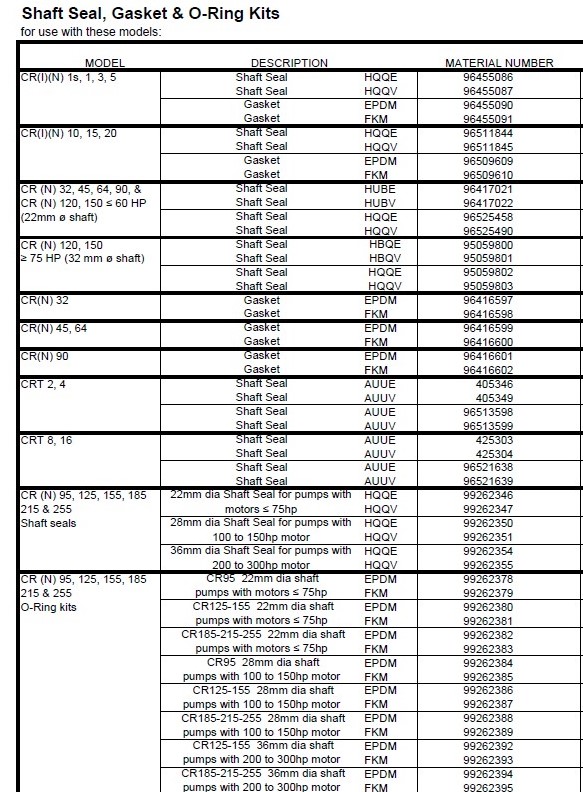

Answer: The shaft seal kit with HQQE seal for the CRE 45-1 is P/N 96525458. Below is the list for the rest of the series.

Question: How do I get the correct replacement Grundfos CRE sensor when the part number is no longer available?

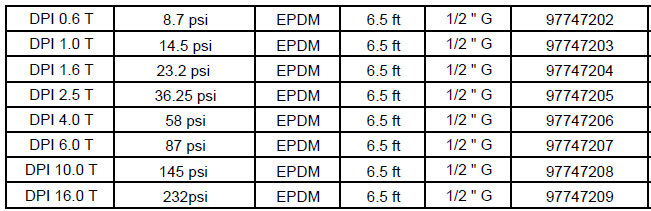

Answer: There are eight sensor options for the CRE-DP models and are rated for the pumps designed differential pressure range. Take the high bar rating off the label and multiply it by 14.5 to get the PSI rating. For example, a 16 bar sensor will be 232 psi which would be the RPI 16.0T from the list of differential pressure (DPI V2 +T) with temperature output sensors below.

If the brass capillary tube for the low pressure side has to be replaced, it is part number 98469210 and also available in stainless steel under part number 99013495. For additional information, contact your local Grundfos rep agency.

Question: What is the part number to replace the seal kit on a CRE-DP 15-1 pump?

Answer: The kit for the 10, 15 and 20 medium series cartridge seal kit is part number 96511844.

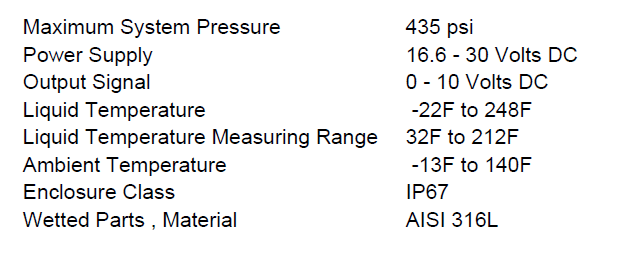

Question: What is the suggested length of pipe distance to the pump’s suction side?

Answer: A minimum of four pipe diameters straight run prior to the suction flange is recommended per the CR Product Guide snapshot below.

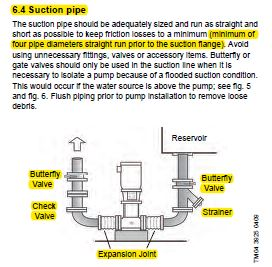

Question: What are the torque settings for mounting a CRE-DP to the housekeeping pad?

Answer: The factory recommend torque settings are 30 ft lbs for the small 1-3-5 series, 37 ft. lbs for the medium 10-15-20 series and 52 ft lbs on the large 32-45-64-90-120 and 150 series. See below for the flange torque settings.

Question: Can a CRE pump be installed in a horizontal position?

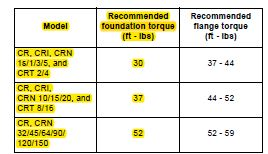

Answer: The pump can be installed vertically or horizontally. Ensure that an adequate supply of cool air reaches the motor cooling fan. The motor must never fall below the horizontal plane.

The arrows on the pump base show the direction of flow of liquid through the pump. To minimize possible noise from the pump, it is advisable to fit expansion joints on either side of the pump and anti-vibration mountings between the foundation and the pump.

Note: Care should be taken to ensure that the vent plug is located in the uppermost position. Isolating valves should be fitted either side of the pump to avoid draining the system if the pump needs to be cleaned, repaired or replaced.

Question: What are the settings for the inputs in multi-pump function control on a Grundfos CRE-DP?

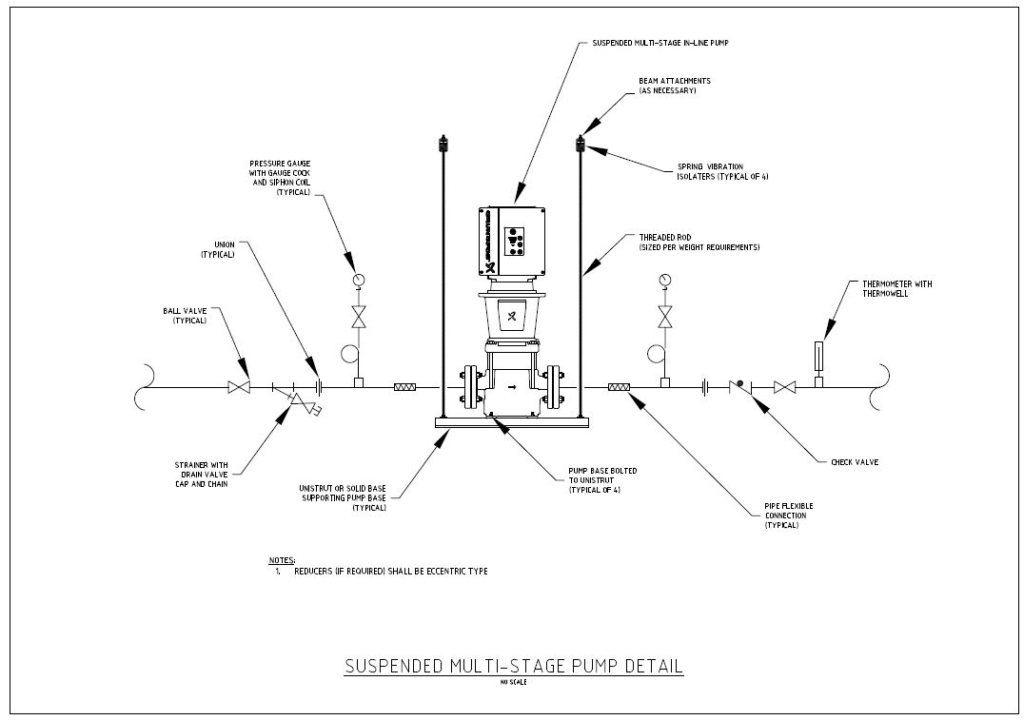

Answer: For the different inputs in multi-pump function, the pump needs to be installed as listed below:

start/stop and two analog-outputs 0-10V is needed for correct control.

In the cascade function, the two output relays shows the two pumps configuration identically on both relays. So if a error will appear on the master pump, then the error will also be shown on the slaves output relay, even if the pump is “ready”.

*There is different settings for the analog input: The temperature sensor, which is used for the heat energy meter: There should only be fitted one sensor to the master pump. (And the heat energy meter should be activated on this pump)

The heat energy meter will always use the total flow in the twin pump as a reference for the accumulated heat energy, which the system of the two pumps is using.

So only connect one sensor to the master and activate the heat energy meter on this one, then the master heat energy meter will represent the heat energy for the twin pump. If the however is connected a sensor input to both the master and the slave pump, then be aware that there will be a difference between the accumulated heat energy date, described below:

The difference between the heat energy shown on the master and the slave pump is simply that the must is using the average temperature between the two pumps, and the slave is only using its own measured temperature. So it will be most correct to use the heat energy meter data from the master pump. Setpoint influence from a external signal: Can be connected to the master only.

Additional operating modes for multi-pump setup.

The multi-pump function enables the control of single-head pumps connected in parallel and twin-head pumps without the use of external controllers. The pumps in a multi-pump system communicate with each other via the wireless GENIair connection.

A multi-pump system is set up via a selected pump, i.e. the master pump (first selected pump). All Grundfos pumps with a wireless GENIair connection can be connected to the multi-pump system. The multi-pump functions are described in the following sections.

start/stop and two analog-outputs 0-10V is needed for correct control.

In the cascade function, the two output relays shows the two pumps configuration identically on both relays. So if a error will appear on the master pump, then the error will also be shown on the slaves output relay, even if the pump is “ready”.

*There is different settings for the analog input: The temperature sensor, which is used for the heat energy meter: There should only be fitted one sensor to the master pump. (And the heat energy meter should be activated on this pump)

-The heat energy meter will always use the total flow in the twin pump as a reference for the accumuluted heat energy, which the system of the two pumps is using.

So only connect one sensor to the master and activate the heat energy meter on this one, then the master heat energy meter will represent the heat energy for the twin pump. If the however is connected a sensor input to both the master and the slave pump, then be aware that there will be a difference between the accumulated heat energy date, described below:

The difference between the heat energy shown on the master and the slave pump is simply that the must is using the average temperature between the two pumps, and the slave is only using its own measured temperature. So it will be most correct to use the heat energy meter data from the master pump. Setpoint influence from a external signal: Can be connected to the master only.

Additional operating modes for multi-pump setup.

The multi-pump function enables the control of single-head pumps connected in parallel and twin-head pumps without the use of external controllers. The pumps in a multi-pump system communicate with each other via the wireless GENIair connection.

A multi-pump system is set up via a selected pump, i.e. the master pump (first selected pump). All Grundfos pumps with a wireless GENIair connection can be connected to the multi-pump system. The multi-pump functions are described in the following sections.

Question: Do vertical CR pumps need to have suction diffusers like base mounted pumps?

Answer: Suction diffusers are not required due to having a engineered flow pattern that does not add turbulence. Aside from not having SD’s, they do not require concrete housekeeping pads or vibration isolation pads. This design takes about 1/5 the floor space as a base mounted pump.

Another benefit to using a vertical stage pump is that instead of having mechanical seals that leak, they use a cartridge seal kit. The repair takes about 30 minutes to changeout.

Question: What parts should we on hand in our maintenance shop have for our Grundfos CR 64-1-1 and CRE-DP 45-1 pumps?

Answer: You will only need to stock just one part for both models, a cartridge seal kit, P/N 96522548.

Question: Can a Grundfos CRE-DP be mounted inline off the floor?

Answer: Yes it can. There are two ways to install it off the floor. The first is to fabricate a stand just like pictured here.

The second option is to suspend it per the factory supplied drawing shown below.

The CR series vertical multi-stage pump is a home run with specifying engineers due to using only 1/5 the space of a comparable base mounted pump. It also includes the VFD, DP sensors and integrated logic controls.

For the installing mechanical contractors, they save cost by no longer having to add suction diffusers, pouring housekeeping pads or hiring subcontractors to install external VFDs.

For additional information, contact your local Grundfos wholesaler.

Question: What is the replacement type of grease for CRE motors?

Answer: The Grundfos MLE motors (up to 5HP) use Lithium based electric motor bearing grease, which is not compatible with polyurea based electric motor greases that are standard in other manufacturer’s motors.

Grundfos uses Mobile Unirex N3 at the MLE factory. This information is printed on a tag on the motor housing. A lithium-based grease compatible with this must be used. The Grundfos order info for the Lithium-based grease Cartridge is P/N. 91079414 and is also available through Grainger. The MLE motors are in the CR, CRE, VLSE and VLSE E-Solutions series (up to 15HP).

For the Baldor motors used on models 15HP and larger, Darmex RPL-707 high temperature grease is recommended as listed in the Grundfos installation and operations manual.

Installers Tip – When commissioning, bring a label maker and leave the re-order numbers for this and the replacement seal cartridge kit labeled on the pump. It’s good professional courtesy for the building owner’s staff for future concerns.

Another useful tip is to use the grease reminder message that automatically shows up on the pump head screen and have the controls contractor add it as a data point to the BMS. It takes the all the guess-work out from when to service them every time.

This subject often gets glossed over but if not paid attention to will cause expensive damage your investment in the pumps.

The factory recommended preventative maintenance is every six months for extreme use, once a year for severe use and every three years for standard use applications. Grundfos E-Solutions MLE models 10 HP and under are permanently sealed with no lubrication required.

For additional information, refer to the installation and operations manual that is supplied with the pump.

Question: Does Grundfos offer condensate package system that you could provide information about?

Answer: Grundfos does not currently offer a condensate pump package in their line. However, Webb Pump, a division of the F W Webb Company partners with Grundfos using the CR series in their custom Pure Pro branded condensate packages.

The proprietary PurePro Stainless Steel Condensate Return System from F.W. Webb is built around the Grundfos immersion-style, vertical multi-stage pump. It is offered in simplex and duplex models, in three standard stainless-steel receiver sizes: 25-gallon, 50-gallon and 100-gallon. The standard duplex model comes complete with a mechanical duplexing level switch and an integral, pre-wired control panel with circuit protection and motor starters.

Options for these systems include sight glasses, temperature gauges, temperature transmitters, as well as stainless steel pump discharge heads. Systems can even be built as vacuum-systems. Keep in mind that the maximum temperature cannot go higher than 180 degrees due to maintaining the NPSH required.

Question: What’s the difference between a Grundfos CR and a CRE-DP?

Answer: The CR is the standard Grundfos multi-stage pump that has been used for years for industrial process and boiler feeds. It is known as a bullet proof pump and a better choice over a base mounted design for higher head applications.

The CRE-DP is the same multi-stage pump but it his configured for HVAC applications. The “E” in the CRE-DP stands for “electronic drive” so it has a integrated VFD. The “DP” refers to the built in Differential Pressure sensors. By having these components along with the most important part, Grundfos self- optimization logic this series is the most energy efficient, reliable and lowest maintenance cost of any pumps in the industry.

For specifiers designing a new building, it is the preferred pump over base mounted models due to taking up about 1/5th the floor space, no longer required is the concrete housekeeping pad, elimination of expense of suction diffusers and a longer life cycle.

For additional information, go to https://grundfos.com.us or contact your local supplier.

Question: Does the Grundfos Go App that we have for our Magnas work on the CRE-DP series? Currently we can change the setpoint but cannot see any additional setting or status information on the pump head. Would like to see more information.

Answer: Yes, the Grundfos Go works on ALL commercial E-Solutions pumps that have MLE motors and drives such as the Magna1, Magna3, TPE3, CRE, CRE-DP, CMBE, HYDRO MPCE series.

From the menu, you can change changes in the setpoint, control mode and a many other options.

Question: I received a replacement stack kit but the gasket and O-ring were not included. What is the part number for a CRE 45-1?

Answer: The shaft seal kit with HQQE seal for the CRE 45-1 is P/N 96525458. Below is the list for the rest of the series.